Automatic cracker packaging machine

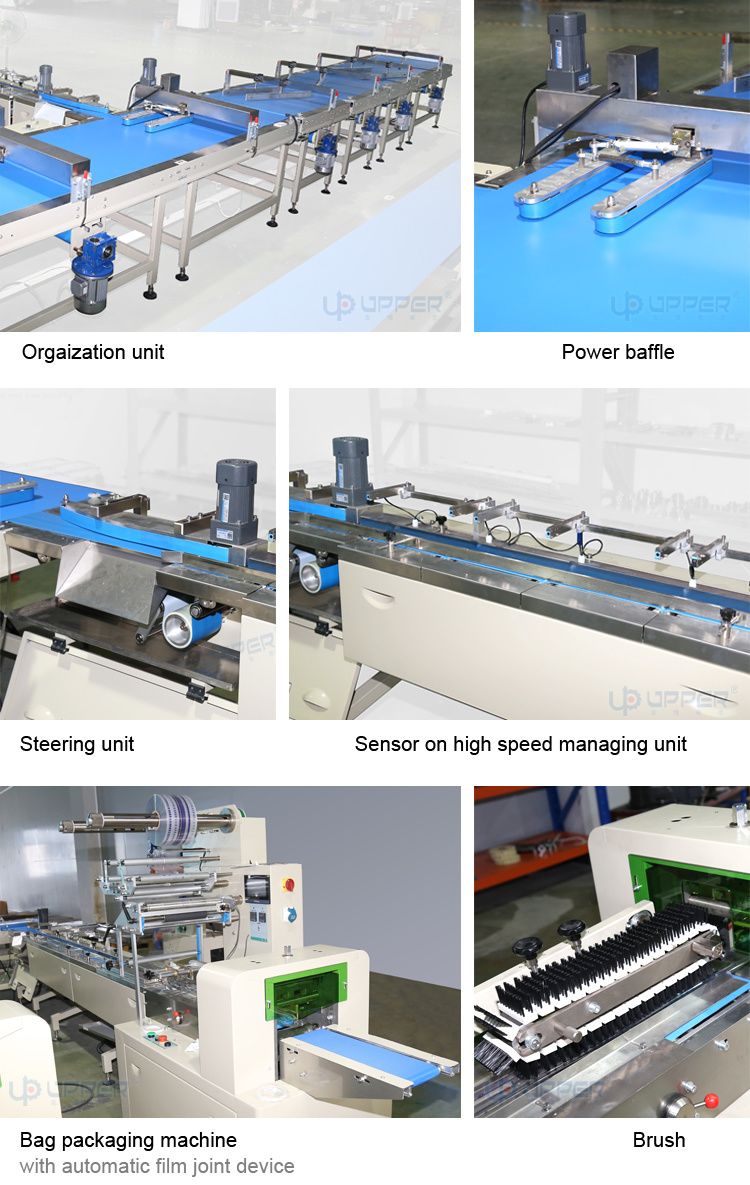

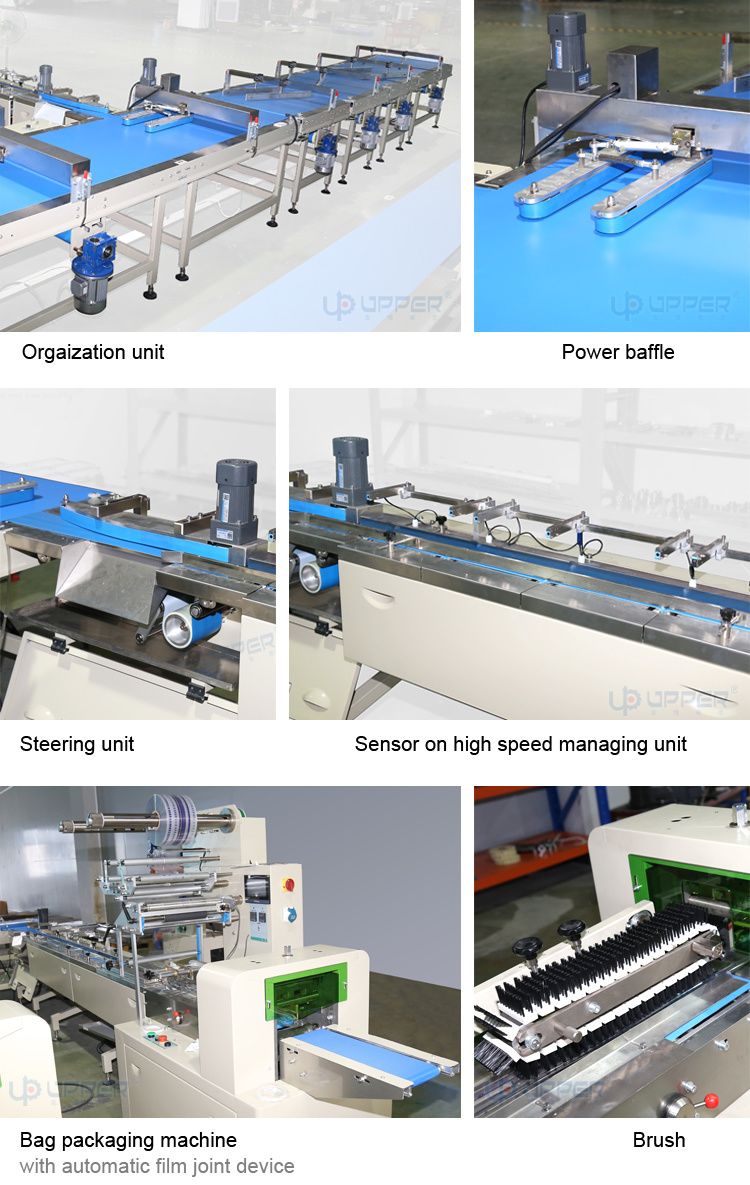

Main Performance And Structure Features:

1. Clear-up,feeding and packing automatically without man-powder operation.

2. Clear-up machine and positioning feeding machine can be operated separately. They can work in

synchronization with producing line, synchronous change speed, automatic stop/startup in case of material

absence/supply and so on.

3. Adopt multi-variable frequency speed control, servo drives control, easy operation, stable running, high of

control preciseness,low energy consumption.

4. To minimize secondary pollution of produts due to traditional manpower arrangement.

5. Clear-up correctly and the speed is up to 200 bags/min with high efficiency.

6. Simple frame, easy maintenance, all conveyor belts can be detached quickly without using any tool,

ensuring food safe and healthy.

| Mode | UPX-CF3 |

| Product name | Automatic bread flow wrapping |

| Product size | 9000×950×1500 mm(According to the actual situation) |

| Master conveyor belt width | 600/800/1000/1200 mm |

| Packing capacity | 50-200 bags/min (per single lane) |

| Power supply | 1ph-220V-50Hz or 3ph-380V-50Hz |

| Application Fields | Food, Daily necessities, Chemicals, Hardware, Medicines. |

| Introduction: |

| The automatic feeding and packaging line, effectively utilizes limited space and is easy to operate. It is suitable for packaging non-breakable items and sticks, such as biscuit, bread, corn cobs, cereal bars, chocolate bars, oily pens, biscuits, teething sticks. |

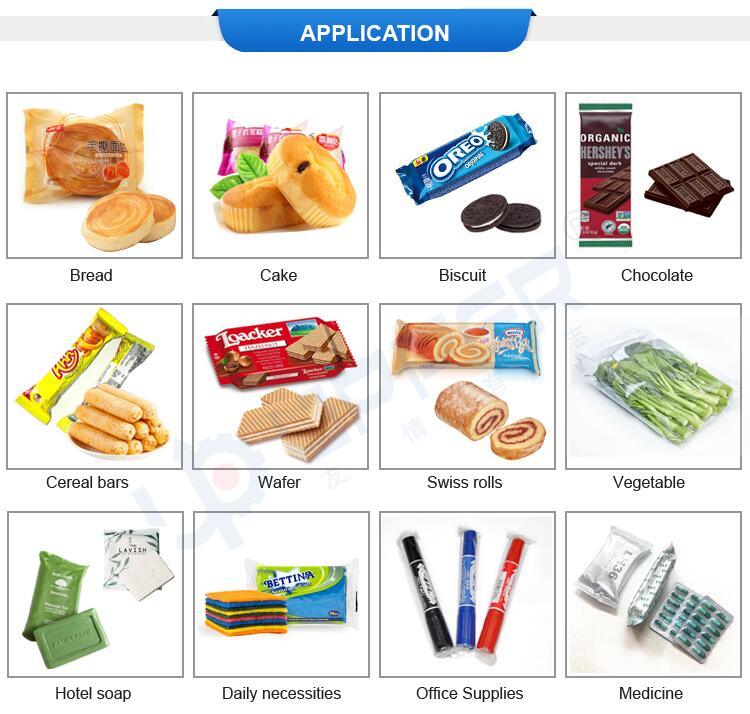

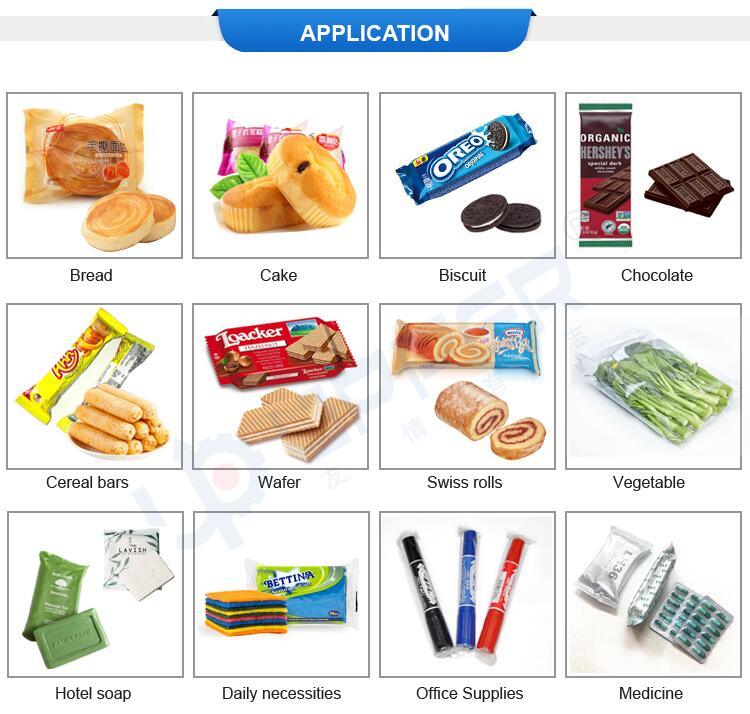

| Application: |

| | Bakery products:

- Bread

- Cake

- Bun

- Hamburger

- Bisuit

- Cookies

- Egg roll

| Dry food

- Chocolate

- Cheese

- Corn bars

- Cereal bars

- Ham sausage

- Instant noodles | Vegetable & Fruit | | Frozen foods

- Ice cream

- Popsicle

- Dumpling

- Steam stuffed bun

- Frozen meat

| Medical supplies

- Mask

- Medical gloves - Medicine

| Daily necessities

| Hardware

| Product with tray |

| Optional auxiliary equipment/function |

| | Date printer - Ink roll printer, thermal transfer printer, ink jet printer

| Labeling machine

| Nitrogen generator

| Metal detector

| Weight detector

| Multi-head weigher

| Deoxidizer sachet feeder

| Seasoning sachet feeder

| Multi-language interface

| Visual Identity System

| Gusset device

| Achol spray device

| Anti-empty bag function

.......

Any other customized function |

| For more product information, please click → | CONTACT US > |

Foshan upper machinery equipment co.,ltd located in Foshan ,Guangdong province ,china. We are

professional design & develop Double transducer horizontal packing machine, flow packing machine,and

fullyautomatic feeding and packing line system Since 2011.Our machine are apply for the industry like food,

hard ware, hotel suppliers, home suppliers, health suppliers, office sullies, medical, toy, electrical components

and plastic products.

We do the OEM/ODM project. Have our engineer team to do the design and develop base on our buyer request.

Quality first ,we do the strict 100% detection to all of the separate part before ship out the machine.

Buy packing machine, choose Our Upper is your smart choose. We will give you the best solution for your packing .

For our process going as below:

1. Our rich experience sales team get your inquiry, clear what you need

2. Our engineer team to do the design base on your request ,make the CAD and other design form.

3. Our purchase department buy the accessories from famous brand or do the import

4. our experience worker make the the machine and go for QC test.

5. After go for the professional packing, ship the goods to buyer .

Our products are welcome by the domestic market, also gain the trust from our over seam clients . Grow with our customer , support the best machine and technology to our buyer is our honor. Welcome to visit our company, and looking forward cooperate with you in the future.

FAQ

Q1: Do you have manual or operation video for us to know more about the machine?

A1: Sure. Manual and operation video are provided. And drawings are available too.

Q2: What's delivery time for the machine after deposit sent ?

A2: Regular delivery time is 7-10 days for packing machine and 30-45 days for fully automatic packing line upon receipt of deposit.Delivery time will be discussed if machine is customized and additional test needed.

Q3: How you pack the machine before shipment ?

A3:Machine is wrapped by plastic film inside and packed with plywood boxes outside which suitable for sea & air shipments.

Q4: How your factory control the machine quality ?

A4: Quality is our culture. We are always focused on: Professional design. High precision for parts processing.

Q5: Which countries have you ever exported your machines to?

A5: USA, Malaysia,India, Indonesia, Russia, Singapore, Lebanon, Saudi Arabia, Yemen, UAE , Mexico, Chile, Argentina, Brazil, Nigeria, Tunis, Algeria, Egypt, Sudan, Cambodia, Pakistan, Bangladesh,South Korea, Turkey, Uzbekistan and Ukraine.

Q6: How can I trust you for the first time business ?

A6: Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q7: What's the language used for the operating system ?

A7: English & Chinese are standard, Optional language will be Spanish, Arabic,French, Russian, German...etc.

Q8: What's the warranty period ?

A8: 12 months after shipment for key components except man made damage & fast moving spare parts.

Q9: What about after-sales service ? Is engineer available to serve oversea?

A9: Yes, but the travel fee is paid by you including daily allowance for the technician. So to save your cost, we will send you a video of full details machine installation and assist you till the end. The video covers installation and operation, as well as maintenance.